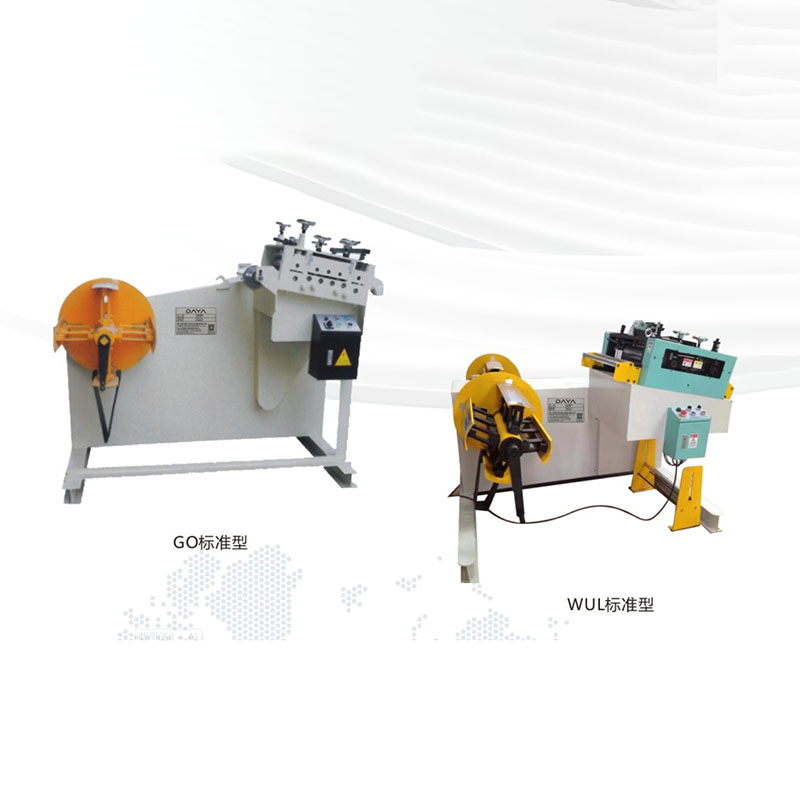

GO, WUL-akateedzera Servo Anopa Muchina

Hunhu

1. Kugadziridza kwematanho kunotora kuverenga kwemagetsi dijitari kuverenga;

2. Yakakwira chaiyo screw inofambiswa neakanaka uye asina kunaka maviri-nzira ruoko mawheel kudzora upamhi kugadzirisa;

3. Iyo kukwirira kwetambo yekudyisa inogadziriswa nemota inosimudzwa erevheta;

4. Chivharo chehomwe chinotenderera chinodzivirira chigadzirwa chinoshandiswa kune sheet sheet;

5. Kudya roller uye kururamisa roller kunoitwa neakakwira chiwanikwa chinotakura simbi (yakaoma chromium yakanamirwa kurapwa);

6. Hydraulic yekutsikirira ruoko mudziyo;

7. Iyo giya mota inotyaira yekudyisa musoro mudziyo weinodzvanya vhiri;

8. Hydraulic otomatiki yekudyisa musoro mudziyo;

9. Hydraulic rutsigiro musoro mudziyo;

10. Iyo yekudyisa sisitimu inodzorwa neMitsubishi PLC chirongwa;

11.Iyo chaiyo yekudyisa inodzorwa neYaskawa servo mota uye yakanyanya kujeka mapuraneti servo yokuderedza;

Zvinoumba maviri mune imwe zvinhu pani uye munoenzanisa muchina:

1. Radhi yezvinhu inosanganiswa nemuchina wekusimudza, uyo usingatore nzvimbo. Zviri nyore kushanda uye kushandisa dhayamita inoshanduka inotsigira chishandiso kugonesa kurodha uye kuburitsa.

2. Inokodzera mhando dzese dzesimbi coil ine hukobvu hwezvinhu zve 0.5-3.0 mm.

3. Inotora yemhando simbi mamiriro muviri, ine yakasimba dhizaini, kugadzikana kushanda, diki basa uye nzvimbo yekuchengetedza.

4. Iyo roller yakagadzirwa nekutakura simbi. Mushure mekurapa kwekupisa uye kudzima kweHRC60, yakaputirwa neyakaomarara chromium uye ikakuyiwa zvakare, iyo inogara yakasimba.

5. Chigadzirwa chebhureki chinogona kugadziriswa kuita kuti coil itenderere zvakanyanya uye nekuwedzera simba rayo mutoro.

6.Kunze magetsi electromagnetic contactor nemagetsi zvigadzirwa zvinoshandiswa zvemagetsi kudzora, zvine zvishoma zvikanganiso uye hupenyu hurefu hwehupenyu.

7. Oiri yekumanikidza kuwedzera kunogona kusarudzwa. Nekuda kwezvinhu zvinorema, zvinokurudzirwa.

Magetsi Hardware, mota yemotokari, zvemuchina Hardware, yemhepo kutonhodza Hardware, yekicheni Hardware stamping otomatiki yakavhurika bhuku yekuenzanisa mashandiro.

Akasarudzika mabhenefiti:

Stamping vashandisi vanofarira kwazvo maviri mune imwe furemu yekumisikidza muchina. Iwo maviri mune imwe zvinhu rack uye yekumisikidza muchina inobatanidza zvinhu rack uye yekumisikidza muchina, iyo inochengetedza zvakanyanya nzvimbo, ine mwero mutengo uye kudhura kuita, uye inowanzo shandiswa michina yekumisikidza yekutsika yekugadzira tambo.

Kuisa uye kugadzirisa nzira:

1. Zvinoenderana neukobvu hwezvinhu zvakasvibirira zvinoshandiswa neyakajairika zvigadzirwa uye kureba kwekudyisa nhanho nhambwe, iyo nhanho pakati peye feeder uye ukobvu hwezvinhu zvakagadzirwa zvinofanirwa kutemerwa. Kana ukobvu hwezvinhu hwakawanda kana nhanho yekudyisa iri yakareba, daro kubva kune rinosimudza rinofanira kuwedzerwa zvakakodzera, zvikasadaro, rinogona kupfupiswa nenzira kwayo.

2.Pakati peiyo yakatwasuka roller inofanirwa kunge ichienderana neiyo roller nzvimbo yeanodyisa uye pakati pebhokisi kufa.

3. Mushure mekunge nzvimbo yekumisikidza iri munzvimbo chaiyo, mabhaudhi epasi pevhu anofanira kugadziriswa kusvika pazvinokwanisika kudzivirira kutama panguva yekumhanyisa kwekupedzisira.

4. Mushure mekumisikidzwa, ndapota isa mafuta antirust pamushini uye zadza mafuta ekuzora.